How to Improve The Measuring Accuracy of The External Clamped Ultrasonic Flowmeter in Practical Applications

Because the external clamp-type ultrasonic flowmeter has many advantages, such as very simple installation, high cost performance, maintenance-free, wide measuring medium, wide range ratio and so on. With the development of electronic technology and software, the external clamp-type ultrasonic flowmeter has gradually become one of the most popular forms of flow measurement.

图1

图1

So, in the actual installation and use, how to improve the measurement accuracy of the ultrasonic flowmeter? First of all, we need to determine the main factors that affect the measurement accuracy, and then make targeted improvements.

Because the ultrasonic flowmeter adopts the measurement principle of the time difference method, the flowmeter emits ultrasonic signals from the outer wall of the pipeline, and then measures the time of such a process as the ultrasonic wave passing through the pipeline material - the fluid - the pipeline material.

图2

图2

Therefore, the following points are the main factors that should be considered when evaluating the measurement error (based on the application of Fuji ultrasonic flowmeters).

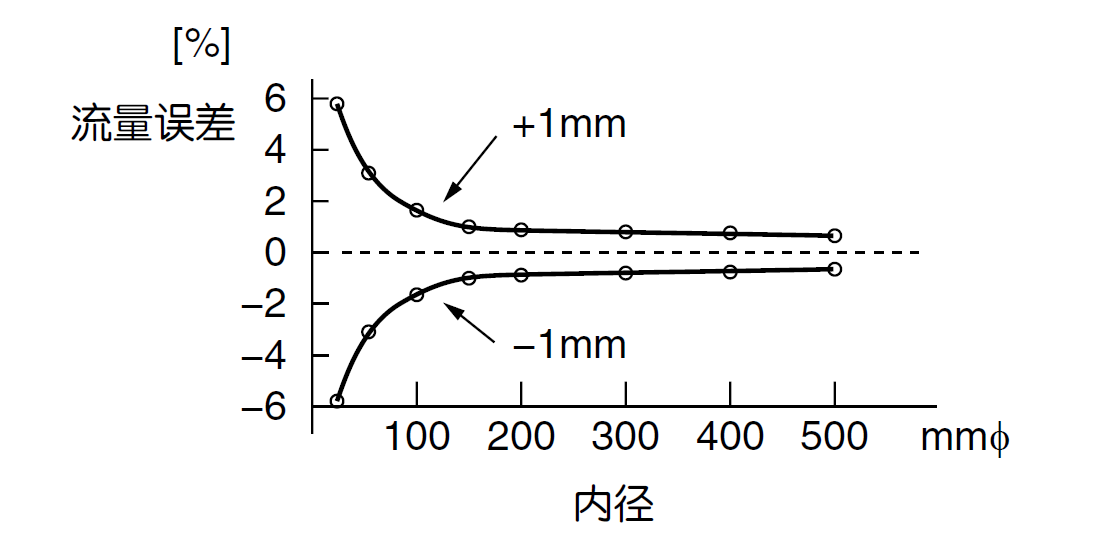

1、Pipe Size

When the set pipe size is different from the actual pipe size, such as the difference in inner diameter size is about 1%, the error obtained by flow conversion is 3% deviation.

(The following is an example of the case where the inside diameter deviates by 1mm)

图3

图3

Before installation on site, the actual pipe diameter and wall thickness must be measured. If the wall thickness cannot be determined, a thickness gauge can be used to measure it.

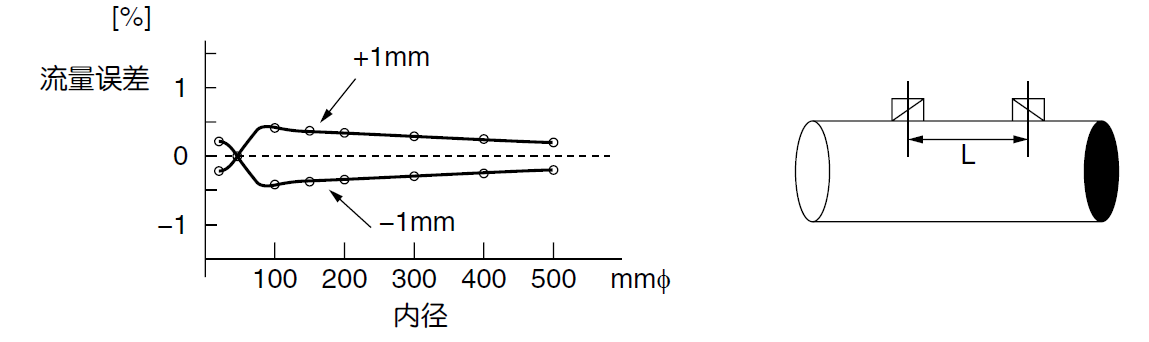

2、Sensor Installation Error

The general standard is that an error of the installation length of ±1mm can bring a flow error of less than 1%.

图4

图4

3、Fluid Turbulence in The Pipeline

When the straight pipe section is short (especially on the upstream side), the fluid will be skewed, which will cause a certain deviation error, or when the liquid flow swirls, the indicator value will fluctuate. Before installing the sensor, be sure to ensure the proper straight pipe distance.

4、Scale or Severe Corrosion in The Pipeline

The error is the same as described in Article 1. If the scale deposits or rust is too severe, the received wave may not be received, making the measurement impossible.

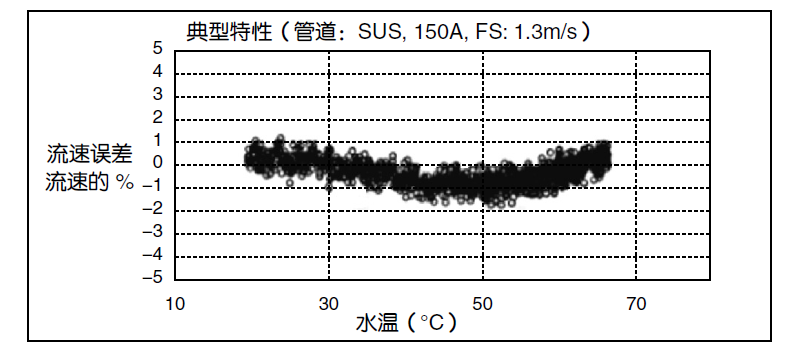

5、Change of Water Temperature

The fluid sound velocity is calculated in real time to compensate for the change of fluid temperature (new sound velocity measurement system), but there is a small amount of error.

图5

图5

6、Output When The Fluid Contains Bubbles

When the fluid contains more bubbles, it will also affect the accuracy of the actual measurement, and if the bubble content exceeds the capacity of the ultrasonic flowmeter, it will be impossible to measure (Fuji ultrasonic flowmeter can resist 12Vol% bubble content).

Shanghai Kekun is a professional instrument sales enterprise, the general agent of Fuji Electric (China) Co., LTD. A full range of products Fuji ultrasonic flowmeter, ultrasonic flowmeter, Fuji flowmeter, Fuji frequency converter, Fuji analyzer The main products are imported ultrasonic flowmeter, portable ultrasonic flowmeter, external clamptype ultrasonic flowmeter, Handheld ultrasonic flowmeter Fixed ultrasonic flowmeter Ultrasonic flowmeter, electromagnetic flowmeter, vortex flowmeter, orifice flowmeter, flowmeter calibration water ultrasonic flowmeter Ultrasonic flowmeter manufacturer ultrasonic flowmeter price clamp type ultrasonic flowmeter.

Ultrasonic flowmeter supplier

Wang Wenxue

Best Regards!

Shanghai Kekun Industrial Technology Development Co., LTD. Fuji ultrasonic flowmeter China general agent

shanghai Kekun Industrail Thecnology Dvelopment Co.,Ltd

Address: Room 206, Building 1, No. 129 Xuanqiu Road, Pudong New Area, Shanghai

Mobile: 15901759876

Email: wangwx2081@163.com

沪公网安备31011502401909

沪公网安备31011502401909