What is sensor

Miniaturization, digitization, intelligentization, multi-function, systematization and networking. It is the primary link to realize automatic detection and automatic control. The existence and development of sensors, so that the object has the sense of touch, taste and smell, so that the object slowly become alive. It is usually divided into ten categories according to its basic sensing function, such as thermal element, photosensor, gas sensor, force sensor, magnetic sensor, humidity sensor, sound sensor, radiation sensor, color sensor and taste sensor.

sensor

Temperature sensor

Temperature sensor refers to a sensor that can sense temperature and convert it into a usable output signal. Temperature sensor is the core part of temperature measuring instrument, and there are many varieties. According to the measurement method can be divided into contact and non-contact two categories, according to the sensor material and electronic component characteristics are divided into thermal resistance and thermocouple two categories.

Contact type

The detection part of the contact temperature sensor has good contact with the measured object, also known as the thermometer. Thermometers achieve thermal balance by conduction or convection, so that the value of the thermometer can directly represent the temperature of the measured object.

Generally, the measurement accuracy is high. The carburized glass thermal resistance made of porous high-silica glass carburizing sintering is a temperature sensing element of low temperature thermometer, which can be used to measure the temperature in the range of 1.6 ~ 300K.

Non-contact type

Its sensitive element does not contact with the measured object, also known as non-contact thermometer. This instrument can be used to measure the surface temperature of moving objects, small targets and objects with small heat capacity or rapid temperature change (transient), and can also be used to measure the temperature distribution of the temperature field. The most commonly used non-contact thermometers are based on the fundamental laws of blackbody radiation and are called radiation thermometers. Radiation thermometry includes luminance (see optical pyrometer), radiation (see radiation pyrometer), and colorimetry (see colorimetric thermometer).

Advantages of non-contact temperature measurement

The upper limit of measurement is not limited by the temperature resistance of the temperature sensing element, so there is no limit to the maximum measurable temperature in principle. For high temperatures above 1800℃, the non-contact temperature measurement method is mainly used. With the development of infrared technology, radiation temperature measurement has gradually expanded from visible light to infrared, and has been used from 700 ° C to room temperature, and the resolution is very high.

Working principle

Resistance sensing

As the temperature of a metal changes, its resistance value also changes.

For different metals, the change in resistance value is different for each change in temperature, and the resistance value can be directly used as an output signal.

There are two types of resistance variations

Positive temperature coefficient

Temperature increase = resistance increase

Temperature decrease = Resistance decrease

Negative temperature coefficient

Temperature increase = resistance decrease

Temperature decrease = resistance increase

Thermocouple sensing

A thermocouple consists of two metal wires of different materials that are welded together at the end. Then measure the ambient temperature of the non-heating part, you can accurately know the temperature of the hot spot. Because it must have two conductors of different materials, it is called a thermocouple. Thermocouples made of different materials are used in different temperature ranges, and their sensitivity is also different. The sensitivity of the thermocouple refers to the change in the output potential difference when the temperature of the hot spot changes by 1℃. For most metal-supported thermocouples, this value is between 5 and 40 microvolts /℃ .

Selection method

Thermoelectric couple

Thermocouples are the most commonly used temperature sensors in temperature measurement. Its main advantages are wide temperature range and adapt to various atmospheric environments, and strong, low price, no power supply, is also the cheapest. A thermocouple consists of two different metal wires (metal A and metal B) connected at one end, and when one end of the thermocouple is heated, there is a potential difference in the thermocouple circuit. Temperature can be calculated by measuring the potential difference.

Thermistor

Thermistors are semiconductor materials, most of which have a negative temperature coefficient, that is, the resistance value decreases with the increase of temperature. Temperature changes can cause large resistance changes, so it is the most sensitive temperature sensor. However, the linearity of the thermistor is very poor, and has a lot to do with the production process. Manufacturers cannot give standardized thermistor curves.

Acceleration sensor

An acceleration sensor is a sensor that measures acceleration. It is usually composed of mass block, damper, elastic element, sensitive element and adaptive circuit. In the process of acceleration, the sensor obtains the acceleration value by measuring the inertia force of the mass block and using Newton's second law. According to the different sensor sensitive elements, common acceleration sensors include capacitive, inductive, strain, piezoresistive, piezoelectric and so on.

Sort

Piezoelectric type

Piezoelectric accelerometer is also called piezoelectric accelerometer. It is also an inertial sensor. The principle of the piezoelectric acceleration sensor is to use the piezoelectric effect of piezoelectric ceramics or quartz crystals. When the accelerometer is shaken, the force exerted by the mass block on the piezoelectric element also changes. When the measured vibration frequency is much lower than the natural frequency of the accelerometer, the force change is proportional to the measured acceleration.

Piezoresistive

Based on the world's leading MEMS silicon micromachining technology, piezoresistive acceleration sensor has the characteristics of small size and low power consumption, easy to integrate in a variety of analog and digital circuits, and is widely used in automotive collision experiments, test instruments, equipment vibration monitoring and other fields.

Capacitive

Capacitive acceleration sensor is a kind of capacitive sensor based on capacitive principle. Capacitive accelerometers/capacitive accelerometers are the most common acceleration sensors. There is no substitute in some areas, such as airbags, mobile phones and mobile devices. Capacitive accelerometers/capacitive accelerometers employ a microelectromechanical system (MEMS) process that becomes economical in mass production, thus guaranteeing a lower cost.

Servo-Type

Servo acceleration sensor is a closed-loop test system, which has the characteristics of good dynamic performance, wide dynamic range and good linearity. Its working principle, the vibration system of the sensor is composed of "M-K" system, the same as the general accelerometer, but the mass m is followed by an electromagnetic coil, when there is an acceleration input on the base, the mass block deviates from the equilibrium position, the displacement size is detected by the displacement sensor, amplified by the servo amplifier and converted into a current output, the current flows through the electromagnetic coil. The electromagnetic restoring force is generated in the magnetic field of the permanent magnet to try to keep the mass block in the original balance position in the instrument housing, so the servo acceleration sensor works in the closed-loop state.

Optical Fiber Sensor

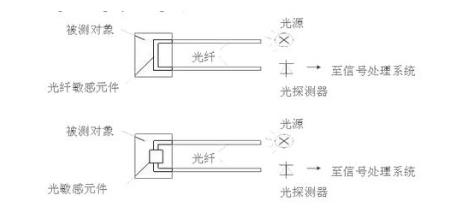

The basic working principle of the optical fiber sensor is to send the optical signal from the light source through the optical fiber into the modulator, so that the parameters to be measured interact with the light entering the modulation area, resulting in changes in the optical properties of the light (such as light intensity, wavelength, frequency, phase, polarization state, etc.), and become the modulated signal source, which is sent into the optical detector through the optical fiber, after demodulation, the measured parameters are obtained.

Principle

The basic working principle of the optical fiber sensor is to send the light from the light source through the optical fiber into the modulator, so that the parameters to be measured interact with the light entering the modulation area, resulting in changes in the optical properties of the light (such as the intensity of the light, wavelength, frequency, phase, polarization state, etc.), called the modulated signal light, and then use the influence of the measurement on the transmission characteristics of the light to complete the measurement.

Working principle of optical fiber sensor

(1) Functional type - made of some sensitive characteristics or functions of the optical fiber itself

(2) Light transmission type - the fiber only plays the role of transmitting light, and it is installed in the end of the fiber or in the middle of other sensitive elements to feel the changes being measured.

Peculiarity

High sensitivity;

The geometric shape has many aspects of adaptability, and can be made into any shape of optical fiber sensor.

Devices that can sense a variety of different physical information (sound, magnetism, temperature, rotation, etc.) can be manufactured;

Can be used for high pressure, electrical noise, high temperature, corrosion, or other harsh environment;

Moreover, it has intrinsic compatibility with optical fiber telemetry.

From: Engineering Control Network

沪公网安备31011502401909

沪公网安备31011502401909