Introduction

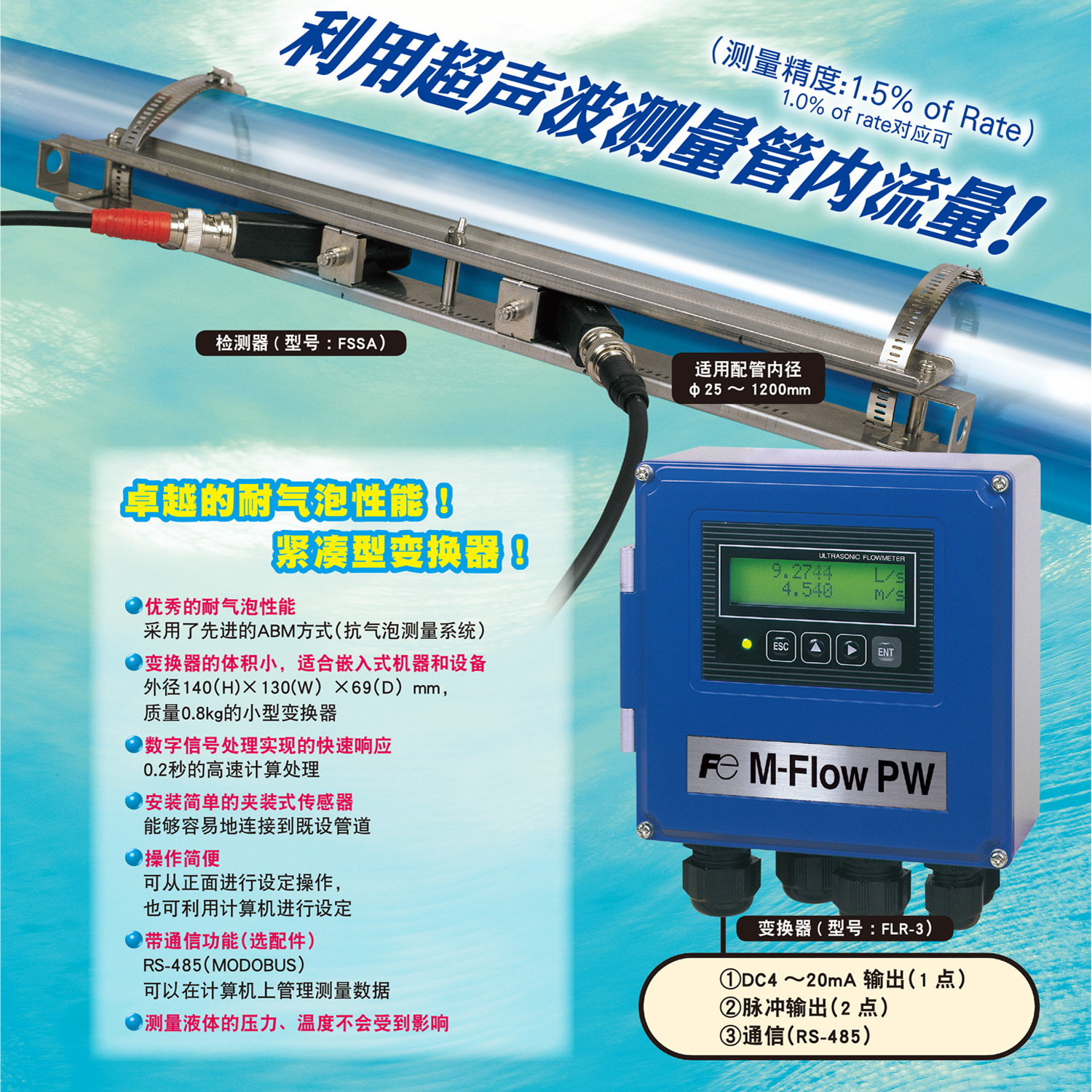

In recent years, ultrasonic flowmeter has been highly praised in the actual application of enterprises, ultrasonic flowmeter not only has good accuracy, stable performance, wide application range, and its installation method is diversified. Today, let's talk about the installation of fixed ultrasonic flowmeters. The installation method of fixed ultrasonic flowmeter is mainly divided into two kinds, one is V method installation and the other is Z method installation in two forms, we will take a look at it.

Installation method is as follows:

1. Installation method V, Z method installation:

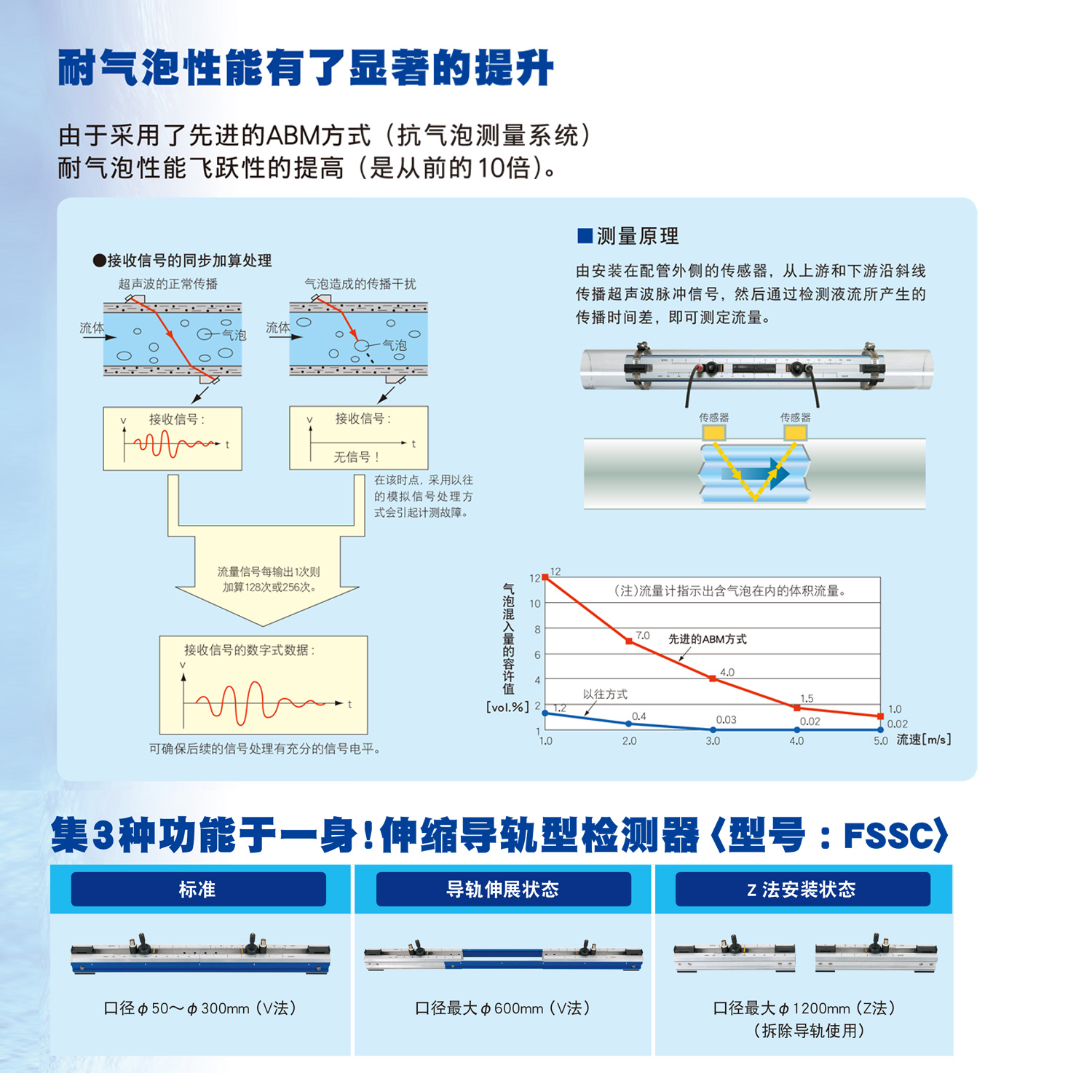

The V method is preferred for DN15mm-200mm pipeline. When installing the two sensors, align them horizontally, and the center line is parallel to the pipeline axis. Note that the emission direction must be relative (the direction of the two sensors is inward). V method has the characteristics of easy to use and accurate measurement. For pipelines with diameter less than DN50mm, the installation accuracy is higher, please pay attention to the parameters of signal strength, signal quality, and transmission time ratio.

The Z method is preferred for DN200mm-6000mm pipelines, and the Z method can also be used when the V method fails to detect the signal or the signal quality is poor. When installing, the vertical distance between the two sensors along the direction of the tube axis is equal to the installation distance, and ensure that the two sensors are on the same axis plane, and pay attention to the emission direction must be relative (the direction of the two sensors is in). Because the Z method is the ultrasonic wave directly transmitted in the medium, the signal is not reflected, so the signal intensity attenuation is minimal. Therefore, Z method has the characteristics of high signal strength and reliable operation.

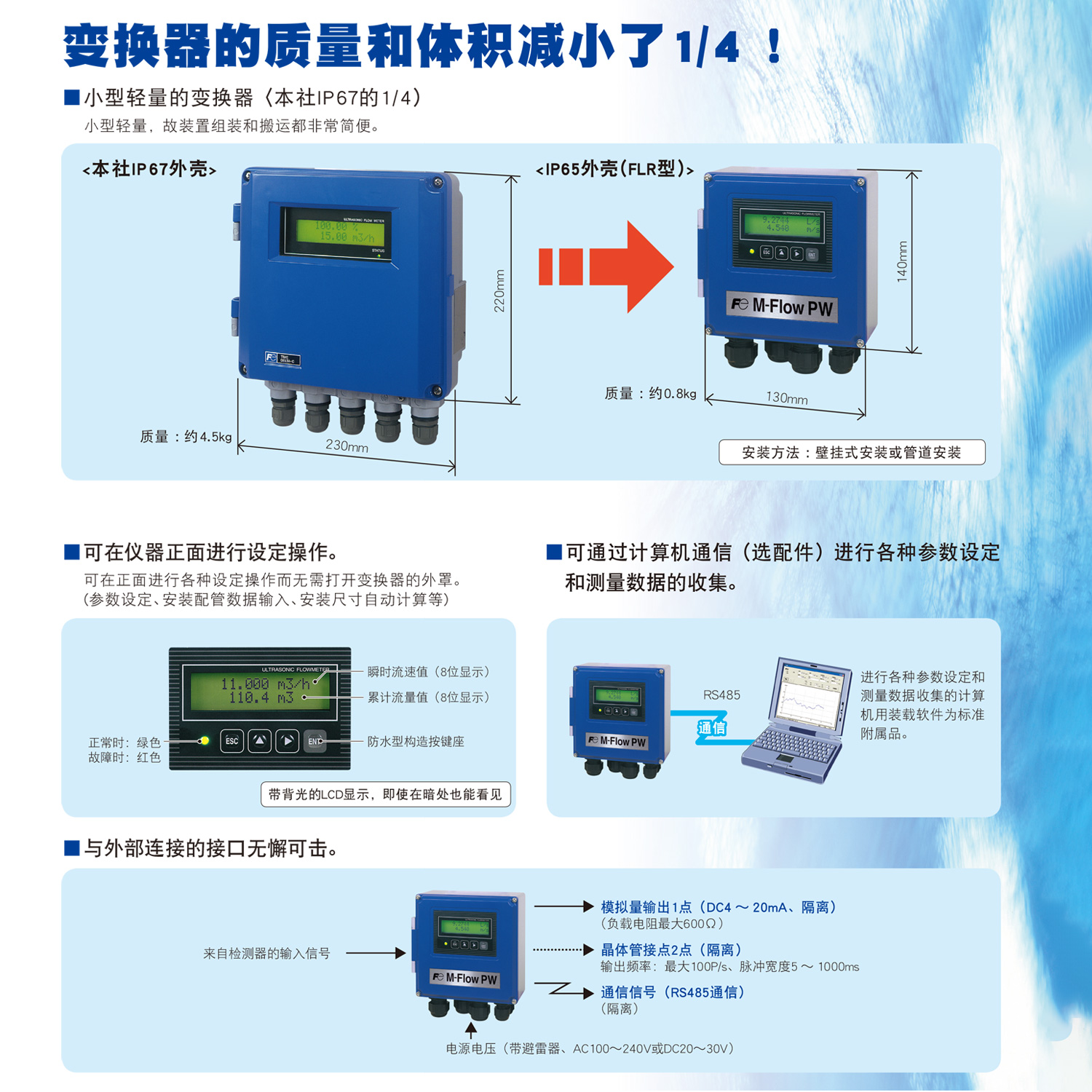

2. Input measurement parameters to get the installation distance

Before starting the measurement, the flowmeter needs to be initially set, usually the 10-26 menu is set item by item (M39 menu has a variety of languages to choose from), after the completion of the setting, the sensor installation distance can be obtained in the M25, which refers to the innermost edge distance of the two sensors, and the sensor is installed according to this data.

3.Handling mounting point

There are two mounting points for fixed ultrasonic flowmeter sensors, which are divided into upstream sensors and downstream sensors. When processing the two installation points, the processing area of one installation point and the size of the probe can be almost, and the processing area of the other installation point should be 2 or 3 times the size of the probe (with the installation point as the center) to facilitate debugging signals. First, clean the area outside the tube where the sensor is to be installed to remove rust and paint. If there is an anti-rust layer should also be removed, Shanghai Youheng suggested that you use a sander to polish out the metallic luster, and then wipe off the oil and dust with a clean rag.

沪公网安备31011502401909

沪公网安备31011502401909